Quotes from our clients:

“Intent Design has been exceptional. We look forward to the continued growth of our relationship.”

“Intent Design’s structured planning, innovation, experience, in-depth knowledge of engineering principles and electromechanical systems and placement of key people in key places made our project successful.”

“Intent Design’s dedication and commitment to the customer is admirable and second to none, reliably delivering on your commitments and meeting or exceeding expectations.”

“The difference between having a satisfied customer and having a disaster has been the solid performance of Intent Design.”

“Our product is a success thanks to the very hard work of the people at Intent Design.”

Case Studies

a. Volvo Nova Bus Door Assembly Installation Analysisb. Innovation Design Example - Recliner Mechanism

c. Innovation Design Example - New Tensioner Design for Restraining Cargo During Shipping

d. Aerospace Military Tank Drop

Case Study - Volvo Nova Bus Door Assembly Installation Analysis

Our Objective:

Improve door assembly installation and reduce costs

Our Scope of Work:

- Problem Analysis, On-Site Documentation and Variation Study

- Tolerance Stack Revision and new GD&T Scheme Development

- Multiple Two and Four Point Installation Jig Design Proposals

- Thirteen Improvement Suggestions

- Revised Construction and Assembly Methods

- Mechanical Design and Engineering of Affected Parts and Assemblies with FEA

- Finalized Jig Design and Engineering with Full 3D Solid Model Documentation and Fabrication Direction

- Senior Level Program Management and Customer Support

Our Results:

- Tolerance Stack and Part Quality Improvement Between 25.6% and 63.4%

- Labor Saving Average 43.5%

- Drastically Reduced Need for Multiple Post-Installation Adjustments in Factory

- Substantial Part Cost and Part Count Reduction

- Future Improvement Opportunities Identified

- Satisfied Customer

Case Study: Innovation Design Example - Recliner Mechanism

Infinite Design Position Locking (IDPL) Mechanism is a new Intent Design Patented invention that uses a wedge geometry created between two plates and a rolling member in between two plates and a rolling member in betwee

Unique Features of the Mechanism are:

Our Scope of Work:

- Infinite Locking positions (continuous)

- Reduced chuck

- Unique operation design to allow travel in only one direction at a time

- Less number of parts

- Compact in size and Less weight

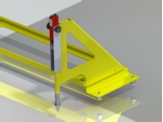

Case Study: Innovation Design Example New Tensioner Design for Restraining Cargo During Shipping

We designed a semi-automated tie down tensioner system for air cargo, marine and industrial tie down restraint. The tensioner system uses extremely low current draw relative to the number of actuations, while able to achieve over 35K lbf. A few of its key differentiators are shown below.

- Low power consumption

- Payload path isolated from the devices’ actuation/operation

- Fully enclosed - protected from dirt

- High number of cycles per charge

- High speed of operation

Aerospace Case Study: Military Tank Drop

Our Objective:

Develop electro-mechanical control systems to drop a military tank from a flying aircraft

Our Scope of Work:

- Intent Design applied its expertise and innovation to perform a complete overhaul of the Cargo Hold System (CHS) and Aerial Delivery System (ADS) within a compressed timeline. Intent Design’s first class systems integration team achieved a rapid scale-up, reduced cycle time and manpower hours, and met the critical deadline for a ground up design concept of the cargo lock system.

- Intent Design engineers and project managers worked on-site with the aircraft and Cargo System manufacturers to closely integrate the Cargo Release System with the Cargo System supplier’s overall logistics solution. Research, modeling, development, and testing were completed in time for the release of the design to prototype manufacturing.

Our Results:

“Intent’s structured planning, innovation, experience, in-depth knowledge of engineering principles and electromechanical systems and placement of key people in key places made this project successful.”